An Introduction

A reliable partner for consumer electronics production and development.

The implementation of digitalization, artificial intelligence technology, and the Internet of Things in practical applications requires efficient electronic components.

In order to meet the rapid iteration and application requirements of consumer electronics products, higher requirements are placed on the flexibility and rapid scalability of automated assembly lines. As a provider of comprehensive laser and automation solutions, Hymson has deployed across the board in the consumer electronics industry, solving various problems for the industry.

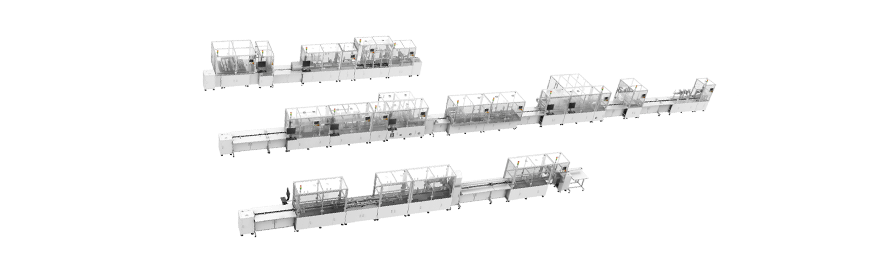

Rice Cooker Packing and

Palletizing Automatic

Packaging Line

3C Battery

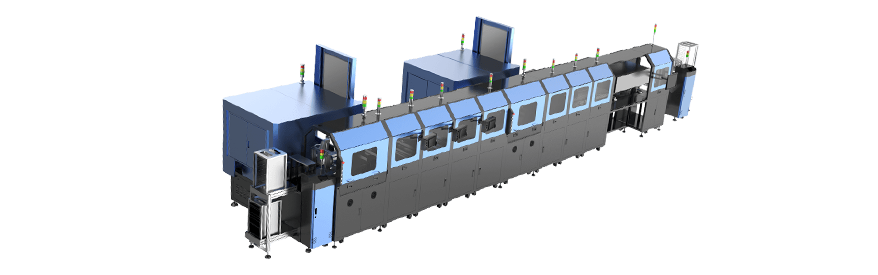

Top Cover Automatic Assembly Line

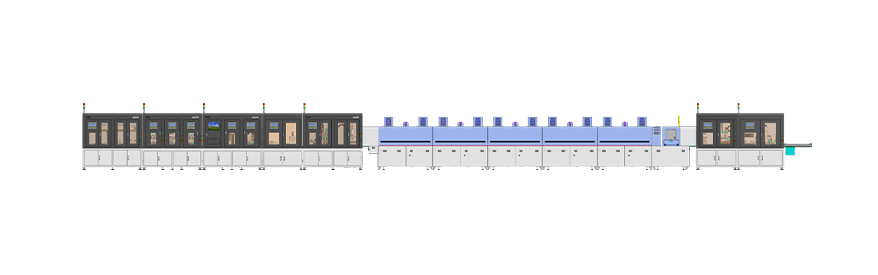

Fully Automatic Steel Case Button Battery Assembly and Packaging Line

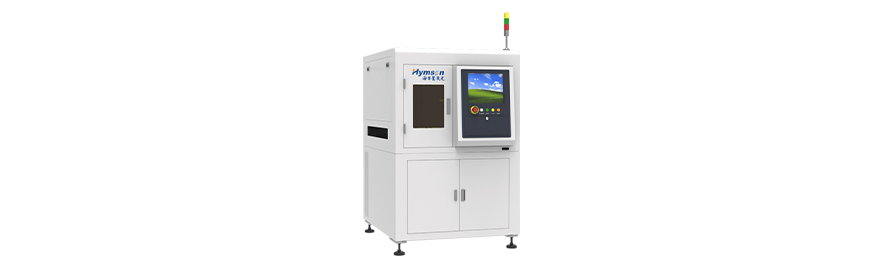

Fully Automatic PCB Laser Marking Machine

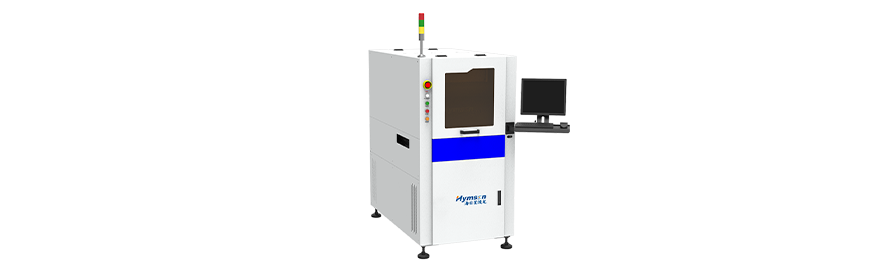

Double Station Laser Cutting Machine

PCB/FPC Online Laser Cutting Machine

Automatic Laser Cutting Machine

Areas of Use

TWS Earphone

TWS EarphoneMES system full closed-loop production control:

The whole line can be digitalized as an option, and various indicators of the line body can be observed in real time.

Strong compatibility:

Compatible with various diameters, thicknesses, lug welding processes, and sealing methods.

Technology leadership:

Adopt the industry's most advanced magnetic levitation transportation positioning technology to achieve fast and accurate positioning (400mm station spacing, 0.8 seconds to complete, positioning accuracy can reach μ level).

Power Transformers

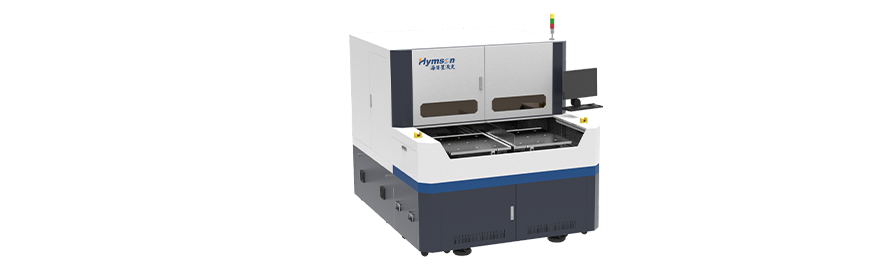

Fully Automatic PCB Laser Marking Machine

Double Station Laser Cutting Machine

PCB/FPC Online Laser Cutting Machine

Automatic Laser Cutting Machine

Planar Transformer Automatic Assembly Line

Transformer Automatic Assembly Line

Areas of Use

Cell Phone

Cell Phone Tablet

Tablet Car Display

Car DisplayMultifunction:

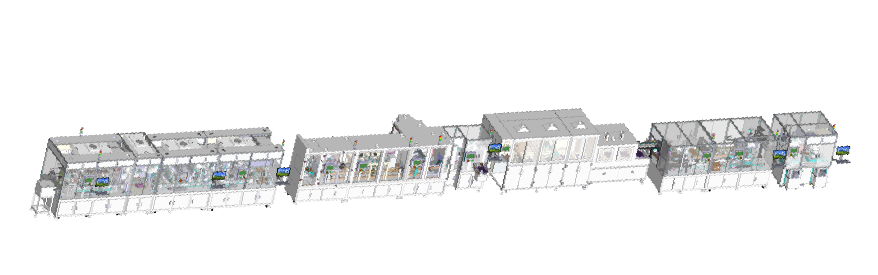

It mainly includes magnetic core loading, dispensing, assembly and electrical performance testing, baking, jig unlocking, printing and blanking and other equipment

Automation experience:

Provided a total of more than 50 complete automated production lines for well-known 3C companies and are currently being used for mass production

Low cost:

Highly standardized design, can be modified at low cost, and quickly used in mass production of similar products

Voice Coil Motor

VCM Motor Automatic Assembly Line

Areas of Use

Voice Coil Motor

Voice Coil MotorPrecise positioning:

1600w dual vision capture positioning + Hymson professional alignment software

Strong compatibility:

Can be used for magnet assembly of VCM motors, SMA motors, etc.

High precision:

The minimum line width is 0.2mm, and the glue volume consistency can reach 99%

Laser Automation

Areas of Use

High productivity:

Equipment UPH 2200, higher than similar equipment UPH1200 in the industry

Strong compatibility:

It is suitable for similar products, and the compatibility can be achieved by replacing the size-related jaw fixtures

Self-developed core light source:

Using high-efficiency semiconductor lasers, stable power and low power consumption

PCB / SMT

Fully Automatic Copper Clad Laminate Marking Machine

Roll to Sheet Cover Film Laser Cutting Machine

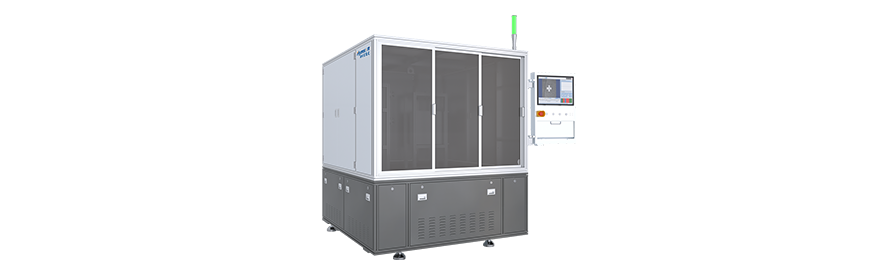

Single Station Laser Cutting Machine

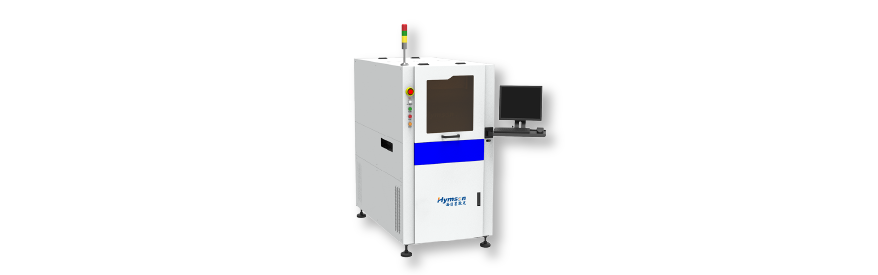

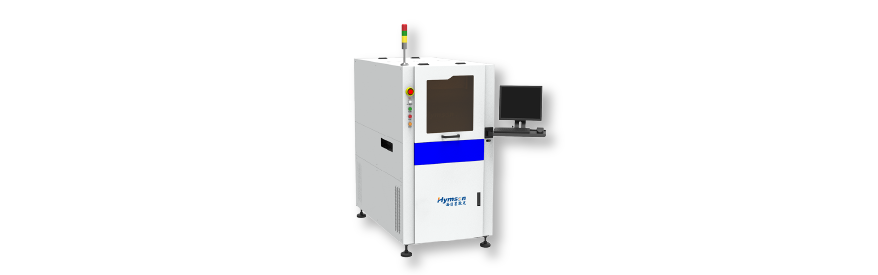

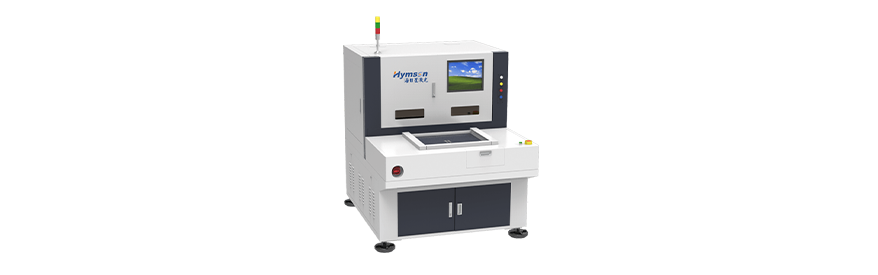

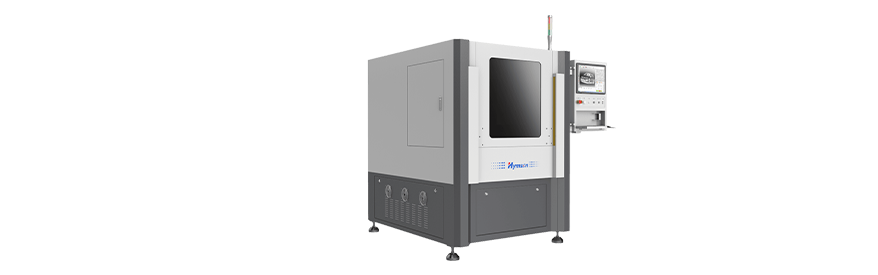

Fully Automatic PCB Laser Marking Machine

Double Station Laser Cutting Machine

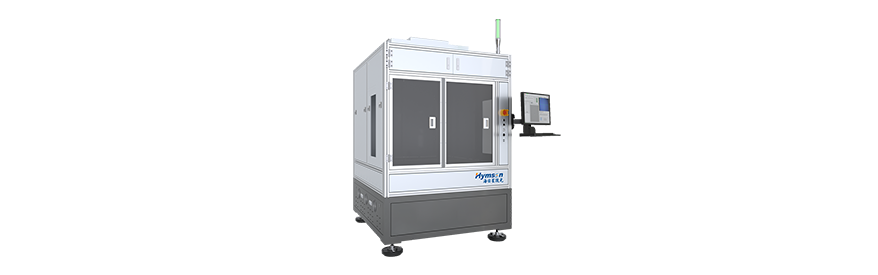

PCB/FPC Online Laser Cutting Machine

Areas of Use

Electronic Circuit

Electronic CircuitHigh productivity and precise visual positioning:

High-precision CCD visual positioning, automatic offset compensation, the equipment integrates laser coding & CCD code reading

Roll-to-roll technology:

Roll-to-roll & roll-to-sheet free switching

High efficiency:

The beam-splitting double-headed synchronous processing system and the power monitoring system have the effects of high production efficiency, stability, and high cutting precision.

Precision Structural Parts

Top Cover Automatic Assembly Line

Five-axis QCW Laser Welding Machine

Precision Laser Cutting Machine

Laser Tape Cutting and Welding Machine

Areas of Use

Laptop

Laptop Cell Phone

Cell Phone Flat

FlatHigh compatibility:

Compatible with different product sizes and thicknesses

High performance:

Precise visual positioning, large field of view capture range.

High precision:

Pattern accuracy and alignment accuracy ≤±10μm.

Brittle Material

Glass Punching Machine

PVD Removal Machine

Glass Invisible Code Reader

Glass Cutting Machine

Areas of Use

Cell Phone

Cell Phone Tablet

Tablet Car Display

Car DisplayWide cutting depth:

The maximum cutting thickness of Hymson glass cutting machine can reach 15mm.

Industry preferred:

PVD removal batch shipment technology is mature, the quality is controllable, and the use efficiency is higher.

Strong scalability

Hymson independently develops lasers and software to provide more differentiated options for processes.

Waterproof Dispensing

Shielding Line

Laser Glue Removal Line

Precision Laser Cutting Machine

High Speed Dispenser

Five-axis Dispensing Machine

Large Format Dispenser

Areas of Use

Cell Phone

Cell Phone Tablet

Tablet Car Display

Car DisplayLow cost:

One machine can be used for multiple purposes

Wide range of dispensing:

X axis 900mm x Y axis 800mm large size product dispensing

Standardization:

Hundreds of automation lines have experience, and the equipment has formed a standardized module.

New Display

Laser Welding Repair Equipment

Fully Automatic Crystal Pusher

Mini LED / Micro LED Fully Automatic Laser Repair and Removal Equipment

Micro LED / Mini LED Laser Mass Welding Equipment

High Precision Laser Automatic Wafer Cutting Machine

Areas of Use

AR Glasses

AR Glasses Cell Phone

Cell PhoneHigh performance laser:

Self-developed advanced laser with good beam quality

Ultra-high machining accuracy:

High-precision micron-level motion platform integration to achieve micro-nano level processing

Intelligent Control System:

Fully automatic intelligent program setting is simple, the accuracy is stable and the efficiency is high

Independent Optical Design:

The independent research and development of optical design capabilities can meet the needs of different application scenarios and form core competitiveness